Testing Equipment

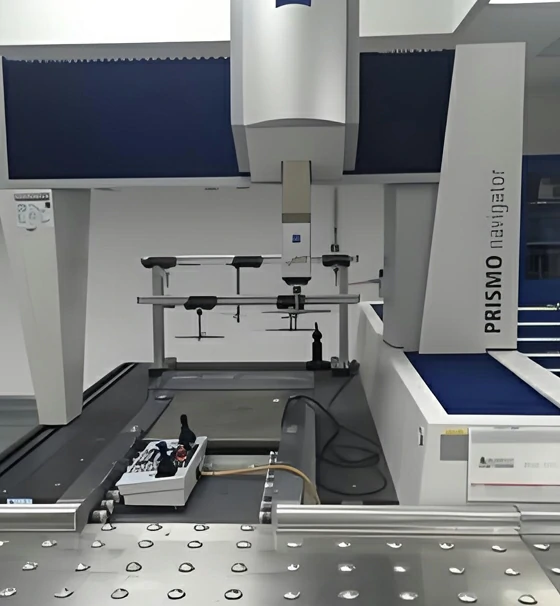

Three Coordinates

High-Precision Measurement

By employing advanced measurement technology, it is possible to accurately measure the dimensions, shape, and position of workpieces, ensuring product quality and production efficiency.

High Degree of Automation

By adopting a computer control system, automatic measurement, calculation, and data processing can be carried out, reducing human errors and improving measurement efficiency.

Strong Universality

Suitable for various types and shapes of workpieces, including parts, assemblies, plastic parts, rubber parts, etc., it has high universality and is applicable to different industries and fields.

Traceability

It can record measurement data of workpieces and generate measurement reports, which can be used for product quality control, production process monitoring, and product traceability.

High Reliability

Employing a precision mechanical system and stable measurement technology enables the maintenance of high-accuracy measurement results over extended periods, promptly identifying and addressing defects and issues in workpieces.

Efficiency

Capable of quickly measuring a large number of workpieces and generating accurate measurement reports, improving production efficiency and reducing costs.

Strong Flexibility

It can be customized and upgraded according to different measurement needs, with high flexibility and adaptability, and can be used in conjunction with other equipment to achieve more efficient automated production lines.

Adapt to Future Development Needs

With the digital transformation of the manufacturing industry and the advancement of intelligent manufacturing, the coordinate measuring instrument can meet the development needs of the future manufacturing industry and has strong adaptability and development potential.

In summary, a coordinate measuring instrument is a high-precision, automated, universal, traceable, reliable, efficient, and flexible measuring device that plays an important role in manufacturing and can effectively improve product quality and production efficiency.

Spectrometer

High-Precision Measurement

By employing advanced measurement technology, it is possible to accurately measure the dimensions, shape, and position of workpieces, ensuring product quality and production efficiency.

High Degree of Automation

By adopting a computer control system, automatic measurement, calculation, and data processing can be carried out, reducing human errors and improving measurement efficiency.

Strong Universality

Suitable for various types and shapes of workpieces, including parts, assemblies, plastic parts, rubber parts, etc., it has high universality and is applicable to different industries and fields.

Traceability

It can record measurement data of workpieces and generate measurement reports, which can be used for product quality control, production process monitoring, and product traceability.

X-ray Detector

Strong Intuitiveness

Directly displaying defect morphology through film or digital imaging is different from indirect waveform interpretation in ultrasonic testing. The imaging principle is that when radiation passes through an object, the difference in absorption of radiation between the defect site and the substrate material creates a contrast.

High Accuracy

It can detect volume defects such as small pores (sensitivity of about 1-2% wall thickness) and slag inclusions, with spatial resolution reaching tens of micrometers.

Good Reliability

The test results can be permanently saved (film or digital file), meeting the traceability requirements of standards such as ISO 17636.

Carbon Sulfur Analyzer

High Precision And Accuracy

The carbon sulfur analyzer adopts advanced analysis technology and precise instrument components to ensure the accuracy and reliability of measurement results.

Instruments are usually equipped with highly sensitive sensors and advanced detection systems, which can accurately measure the carbon and sulfur content in samples.

High Degree Of Automation

Modern carbon sulfur analyzers are typically equipped with automated control systems that can automatically complete steps such as sample weighing, combustion, gas analysis, data processing, and result output.

This greatly improves work efficiency, reduces manual intervention and errors.

Versatility

Some carbon and sulfur analyzers not only have the function of analyzing carbon and sulfur elements, but also can analyze other elements such as nitrogen, oxygen, etc.

This enables the instrument to meet the diverse analytical needs of users.

Widely Applicable Fields

Carbon sulfur analyzers are widely used in various fields such as metallurgy, machinery, chemical engineering, and environmental monitoring.

It can be used to determine the carbon and sulfur content in various materials such as steel, non-ferrous metals, ores, soil, etc., providing data support for quality control, alloy design, and production process optimization.

Easy To Operate And Maintain

Carbon sulfur analyzers are widely used in various fields such as metallurgy, machinery, chemical engineering, and environmental monitoring.

It can be used to determine the carbon and sulfur content in various materials such as steel, non-ferrous metals, ores, soil, etc., providing data support for quality control, alloy design, and production process optimization.